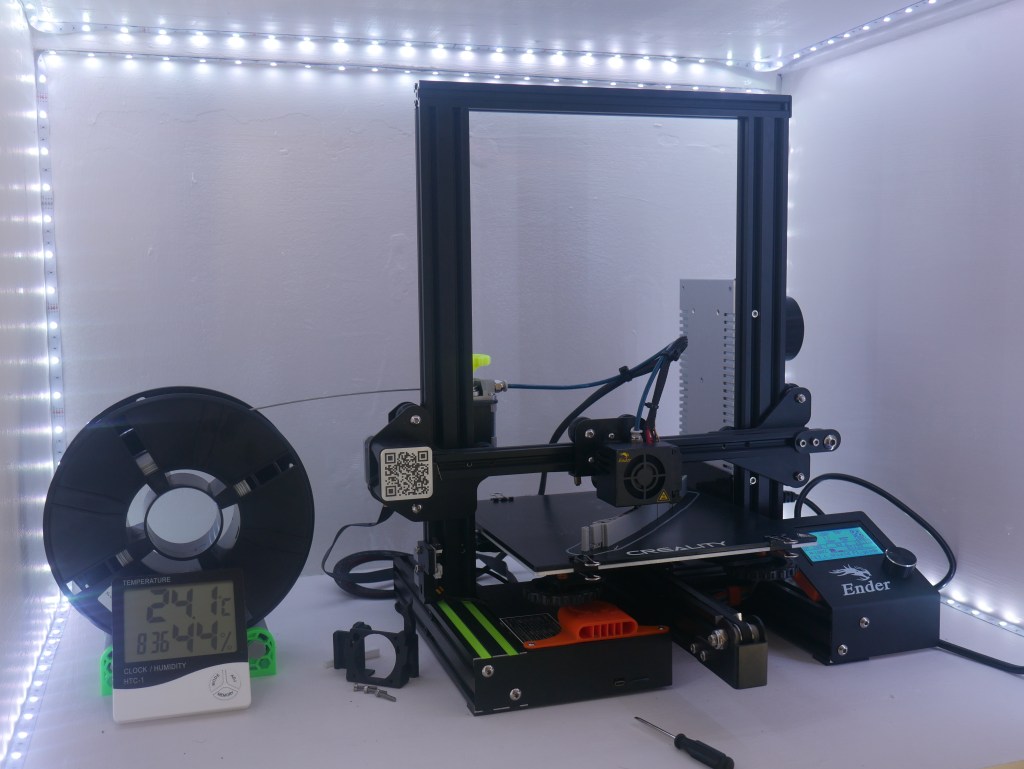

Welcome, are you looking for some information on how to level your Ender 3 (Pro Included) print bed? Then you are in the right spot. This is the method that I use to level my printer bed and keep it level. This method can be used on a whole range of printers( as long as they are similar to a stock ender 3). Welcome to my Ender 3 Bed Levelling method.

When I got my first ender 3 I found it difficult to keep a consistent bed level. This is a problem that many beginners find themselves encountering because, you know, you are a beginner. but no worries, we all start somewhere and I hope that this will help you.

You might be inclined to go onto youtube and find a video explaining the paper method. If you have then I would tell you that I have found this method to be a very inaccurate procedure for bed levelling. I am guilty myself of using this method and where it might “feel” correct, there are more accurate ways to achieve a level bed.

I started with the normal bed and the paper method, but I found this method to be inaccurate. So I upgraded to a glass bed and a 0.2mm feeler gauge. I would highly recommend you do too, I actually explain why you should upgrade to a glass bed here if you are interested. The method I am about to share can be done on either a normal printer bed or a glass bed. But be aware results may vary. The glass bed is more solid and offers no surface depression compared to a stock ender 3 build plate.

Ender 3 Bed Levelling Method

Levelling the bed consists of adjusting the distance between the nozzle and the bed across the entirety of the build surface. The nozzle will be set equally and at the same distance from the print bed across the entire print bed. This will ensure the nozzle will print the perfect first layer for your print. Any change to this distance at any corner will result in less desirable results.

Before Proceeding, Please Note:

The print bed should be preheated before the levelling procedure begins. Especially if you have a glass print bed. The print bed will expand with heat. If you don’t preheat the bed, once it heats up the print the bed will actually be closer to the nozzle than beforehand. So preheat the bed first and then use the following bed levelling procedure.

Lets Begin

- Autohome the printer nozzle, taking care that the nozzle doesnt collide with the printer bed, you may have to lower the bed fully at the beginneing depending on the height and ”stiffness” of the bed springs and Z-limit offswitch.

- Using the printer controls move you nozzle to the front left corner of the bed.

- Use the 0.2mm feeler gauge and place it under the nozzle.

- Raise or lower the printer bed using the knob underneathe until you feel slight restistance when you move the feeler gauge.

- Auto home after setting the cornor.

- Move print nozzle with printer controls and check centre of buildplate with feeler gauge.

- Repeat steps 2-5 for each cornor and centre.

Checking the centre of the build plate after each corner set will allow you to see if the centre of your build plate is being set to the correct distance. This is important especially if you have the normal build plate because these plates can warp and the centre may not be where you expect it to be.

The centre of the build plate will change height after each corner is sent, so make sure to check it at the very end. If you are finding the centre is still not set, look at moving its closure by moving all four knobs the same quarter turn until it’s set. I would proceed to check each of the corners again just to be sure.

I usually perform this method as many times as possible until I achieve a levelled bed. You can also a baby step down the nozzle if you want to achieve more ‘squish’.

How to improve the bed levelling process?

Change the Springs on the Leveling screws: The springs that come stock with the Ender 3 aren’t really that stiff. So with any slight movement of the knob or bed, there is a chance of them loosening, which, changes the bed height. You can upgrade the springs too much stiffer ones which will improve the overall stiffness of the bed.

Use a glass bed: You can check out a full post on:

”Why You Need To Use A Glass Bed On Your 3D Printer!”

Use A feeler Gauge: A feeler gauge is a tool used to measure gap widths. Feeler gauges are mostly used in engineering to measure the clearance between two parts. They are very accurate and reach a very low tolerance, which is ideal for measuring the distance between your bed and the nozzle.

Conclusion

With this process, I have gone from levelling my bed a few times a week to a few times a month. As long as I let the bed cool completely and don’t try to force prints off that is. It is important to let the parts cool completely, any external movement on the bed can change the level. Which will then require you to completely relevel the print bed again. So just wait a little bit longer, please.

I hope this wee tutorial has helped. There are many different ways to level a bed, but this is the one that I have landed on myself. It may take you a few tries to nail down this method, but I’m sure you will be able to handle it.

Find me on Instagram

Support me on Patreon

Watch me on Youtube

My Linktree

Donations: Buy Me A Coffee

Prop Models Available here: Etsy Store

Estikuma

Freelance designer & Mechanical Engineer.

Over Engineering Prop Designer.